Making a masterpiece out of every work piece that you cut sometimes is as simple as sharpening your router bits, but sharpening router bits is not as easy.

You might think that you are an expert, but wait until you read through this article and find out that there is a lot more that you did not know on how to sharpen router bits.

If you are a Newbie looking for a credible source of knowledge into router bits sharpening, then this piece will help you. Blunt bits will have your work pieces make sad faces at you, pathetic jobs.

A lot of things can all go wrong, due to a dull router bit. These include tear outs, excessive feed pressure, or burning.

The solution to all these mishaps might just be lying in sharpening your router bits. Before you resort to sharpening, you might want to clean up the bit first to clean up crud around the edges.

Sometimes cleaning the bit could solve what you thought was a blunt bit. If it doesn’t, it is still an important part of the process.

You will also learn that several other things relate to sharpening router bits such as router bits maintenance and proper routing practices.

I am making sure to include all of these things so that you will not have to look for that information from some other place.

Signs Of A Blunt Router Bit

To tell for the blunt router bit, run it through your fingernail an if it just slides through without making a shaving, and then your bit is blunt.

But before you come to this there is the common overheating, which only holds true if you didn’t get overheating before. Then there is the blackening of the work pieces, which serve as a clear indicator.

The blackening of the work pieces to the left of this illustration are indicators of a blunt router bit. The fine images on the right shows the results after sharpening the bits.

Avoiding false positives

You could diagnose a router for being blunt while in the real sense it is not. If you have set your router to very high speeds, then it is prone to overheating as a cause of the high speeds.

Also if you are trying to make very deep cuts at once, it is almost inevitable that there will be resulting blackening.

Choice of sharpening tools

Of course, you will need a file. A diamond needle file is the best as it will work for the smallest to largest of the bits.

You will get the best results if you use fine or extra fine abrasives, the grit size for these abrasives are usually 600 and 1200 respectively.

Normally, some people will sharpen their routers while holding them by hand, but often such people end up destroying the bits.

You might want to use a chuck. You can alternatively use the router collet if you have one. The wrong choice of abrasive, which would be the use of coarse abrasives, could fracture the router`s edges.

Tips to doing it right

The most basic of tips is that you will require a good light source. Also, comfort is vital in ensuring for an excellent job.

Your point of interest will be the face of the flute, meaning that you will have to keep off the outside edges. Ensure that as much as possible, you sharpen uniformly.

A non-uniform sharpening will alter the balance of the router, which will translate to the smoothness of the cut.

Uniform sharpening means giving each flute a uniform number of strokes as you rotate through the flutes until you get the sharpness that you require.

Consider using some lubricant for effective sharpening. Lubricating also prevents excessive clogging of your abrasives. You can tell if the router is sharp enough by feeling the edges. It should also show no flecks when you look it under a strong light.

Using file abrasives

Remove pilot bearings if any

For bits that have a pilot bearing, always remove it if it is removable. Mistakenly the pilot bearing at any spot will ruin it, and make the whole router useless.

Cleaning

Remove build up by cleaning the router using a brush. Feel free to use a cleaner that will help you make for the cleanest router. Such a cleaner is the oven cleaner.

Honing

After cleaning it is time to sharpen. When working with abrasives, you can over hone the edges. So, you should keep strokes at a minimum as you alternate the edges. You should start with the fine file and then finish using the extra fine file.

Using a diamond wheel

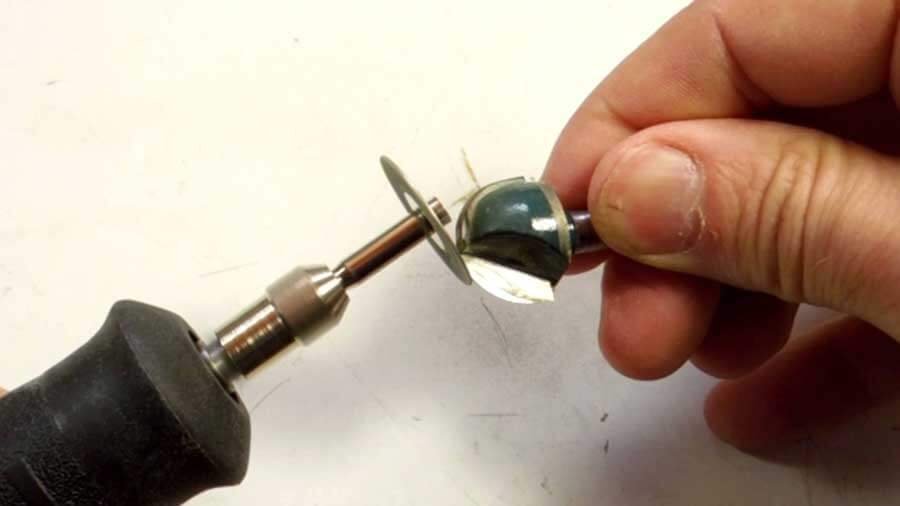

An alternative to sharpening router bits using a file is the use of a diamond wheel. Diamond wheels allow for faster and finer finishing. Once you are equipped with the diamond wheel, you will also need a dermal tool.

The figure illustrates the use of a diamond wheel. You can choose to secure the router bit or to hold it by hand.

Step 1: securing the router bit

Securing the router bit is essential especially for those that don’t have a strong grip. Holding the bit by hand is also tedious so you should consider securing the bit to a workbench. The downside to securing it to a workbench is you will have to repeat the process of securing multiple times you rotate through the flutes.

Step 2: Sharpening

As a rule of thumb, it is recommended that you always start with the flat parts. Then proceed to the edges. I would prefer leaving the edges to professional sharpeners. Ensure to maintain uniform pressure all over the edges to prevent over sharpening some parts.

Note

An important note to make is that there are different types of router bits. As such the important thing to remember is to keep to the flat surfaces of the router bits. Different configurations of the router bit give for different applications. As such let’s get sample types of configurations. You will also learn that the configuration dictates the type of sharpening tool most suitable, either the needle file or the diamond wheel.

Router maintenance tips

After every use of the router always make it a habit to clean the bits by blowing off the dust. Also, use a resin remover to prevent accumulation and subsequent hardening of the resin. It affects the cutting efficiency of the bits. Dirty shanks encourage the development of blurs and rust that inhibit proper tightening of the router bits. Oiling the router bits could result in rust. So, instead wipe them dry and store appropriately.

Always make it a practice to use coolants on the bits while routing. The routing process causes friction and heat buildup that contributes to wear of the router bits. Deteriorating edges indicate that it is time to do a complete makeover by replacing the bits.

Making clean cuts with routers

The first step into making clean cuts with routers is by ensuring for clean and sharp router bits. ½” bits usually result in much fewer vibrations hence giving for finer cuts. Before you start routing, you should always ensure that the bit is properly installed to ensure it doesn’t come loose during operation.

While working with different types of woods ensure to match the speed with the wood type. Slower speed and a high feed work best for some wood while others will finish just fine with high speeds. You should also ensure that you clear off the chips between the work pieces and the router bits as they hinder proper machining.

It is always recommended to make many light cuts rather than one heavy cut that will most definitely result in blackening, and inevitably heat buildup. Making heavy cuts also impacts a heavy load on the bits that results in bits getting dull and wear fast. You should also secure the work pieces tightly to ensure that they do not move to ensure for consistent feeding.

It is also important to route in the right direction to ensure proper contact of the bit with the stock. While working on outside edges you should rotate the bit in the anti-clockwise direction, and in the clockwise direction for inside edges.

[su_youtube_advanced url=”https://www.youtube.com/watch?v=HqS5KAaltCg” controls=”no” showinfo=”no” rel=”no” modestbranding=”yes” https=”yes”]Final Verdict

Now you know how to sharpen router bits. Every expert will tell you that you need a professional to do the real sharpening. This guide equips you with the knowledge to retouch your bits in between visits to the professional sharpeners. Learning to sharpen you router reduces the trips that you will have to make to professional sharpeners.

You do not have to always run to them when the bit gets slightly blunt. You as well have got information on how to correctly diagnose for blunt router bits.

Remember proper use and maintenance also plays a great role. The right practices will see for sustained sharpness, so you do not have to sharpen the bits a dozen times. Remember every sharpening exercise comes with wear and tear.