It could be quite annoying when your drill bits become dull and become less productive. Of course, you will need to change the bits, but what happens when you have no clue on how to do it?

I made this guide to give you more details on how to change drill bits black and decker.

Changing drill bits could be a hard task that you may want to seek professionals to do it for you or even ask for help from one of your friends.

However, we may not get that help all the time which makes it necessary to master the changing process.

What You Need To Know

Drill bits black and decker is built in two types; the cordless and the corded drill. The cordless black and decker use a keyless chuck while the corded drill uses a key chuck system.

Since chucks come in two different types which are keyless and keyed chuck. It is a fact that the process of changing them is different.

It is important to master the two methods of changing bits if you are going to be using the drill tool often. For this reason, in this guide, I will be talking about both of them.

Changing Bits With Keyed Chuck

Step 1: Stopping the drill

To begin the process you start by releasing the trigger then give some time the drill to completely stop, after which you unplug the drill from the electricity supply.

Step 2: Inserting the chuck key

Keyed chucks normally come with a chuck key which you will be using to loosen the chuck and usually located somewhere in the drill.

Holding the chuck key on one of your hands carefully insert the chuck key into the hole on the chuck making sure that the teeth of the chuck key line up perfectly with the teeth on the chunk.

Step 3: Opening the chuck

Holding the drill in one hand, slowly turn the chuck key in a clockwise direction using the other hand. The aim is to open the jaws on the chuck, hence keep turning until the chuck opens allowing you enough space to remove the drill bit by sliding.

Step 4: Removing the bit

After loosening the chuck completely, remove the bit by pulling it out with your thumb and index finger. You may also just turn the drill so that it is facing down, dropping the drill but only if you have opened the chuck wide enough.

Step 5: Inserting new bit

After removing the old bit, insert the new bit carefully while keeping the chuck wide open for smooth insertion. Ensure that your bit is inserted with its shank going first and facing the jaws of the chuck.

Step 6: Tightening the chuck

Firmly holding the bit in a stable position with one of your hands, turn the chuck key clockwise using your other hand until the chuck jaws are tightened.

Always make sure that the bit is secured by ensuring that you tighten well to give it a firm grip then start your drill to test if it’s working perfectly.

If you are not comfortable with it, repeat the procedure making adjustments that you feel fit but if your drill has tested to work perfectly, keep the job rolling!

Changing bits on a keyless drill

Step 1: Loosening the chuck

To loosen the chuck you need to grasp the chunk using one of your hands while holding firmly the drill on your other hand. Twist the chuck gently so that it is moving in an anticlockwise direction thereby loosening the grip.

Step 2: Removing the bit

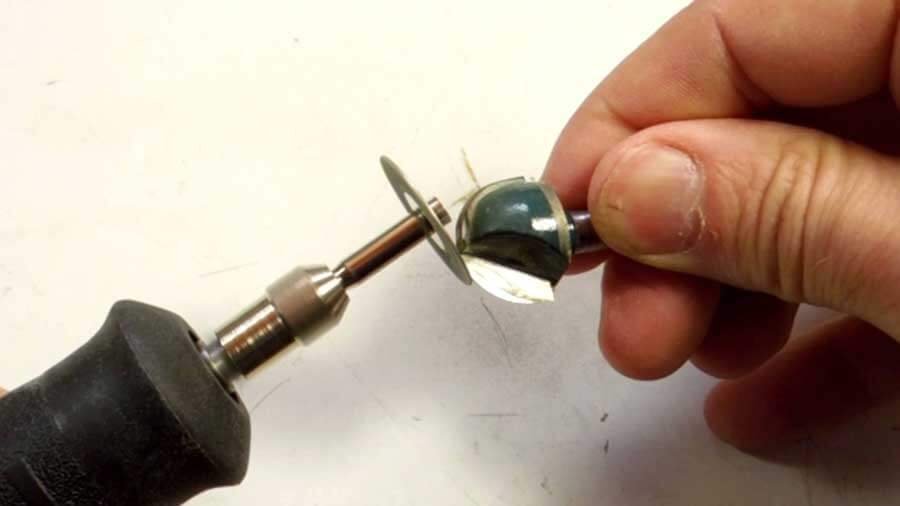

Now that you have loosened the chuck, grip the tip of the bit using your thumb and your index finger so that you are holding it firmly, then pull it out gently.

Step 3: Setting the bit

After removing the old bit definitely, the next step is replacing it with a new one. To do this, hold the new bit firmly using your thumb and the index finger.

Gently insert the new bit into the chuck with its smooth part facing the jaws of the chuck. When you feel that it is in position, pull it back a bit to the length of approximately one centimeter.

Keep holding the bit and the chuck in the position since the bit is not yet gripped and could easily fall out of position.

Step 4: Tightening the bit

While still holding the bit in place carefully and slowly squeeze the trigger to grip the bit in place. Always keep holding the bit while squeezing to ensure that it is perfectly tightened at a straight position.

Now that your bit is changed, start the drill to test it if it is working perfectly. If it is there are mistakes made, repeat the procedure making adjustments keenly but if you are comfortable with it, then your drill is ready for the job.

Final Words

If you are a regular user of drill machine then at one point of time its bit will get dull or might even break and hence replacing it will be of great necessity.

Considering that there are two types of the drill, depending on which type you will be using, you need to know how to fix it if need be and this guide will be quite useful if you are new to changing drill bits.

However, there could be light accidents encountered when changing the drill bits, maybe by just a slip or the drill falling when handling it. You should be careful when undertaking this process and avoid distractions.

From, this simple guide on how to change drill bits black and decker, your bits changing process is made quite simple. The steps are laid down perfectly in a systematic way to ensure that everything falls into position.